pqr impact test|pqr test interpretation : wholesalers If I add the toughness tests to a PQR, can I still use that PQR for another WPS without including the toughness testing? I.e, two different PQR numbers/documents but both . Follow @68hjXyA9bQInIuv on Twitter to see their latest posts, videos and photos. You can also interact with other users who share similar interests, such as gaming, anime and .

{plog:ftitle_list}

Últimas notícias do Acre no site do ac24horas.com. Acompa.

i want to qualify a wps for 6mm to 32mm with impact test. but i have two pqrs already qualufied. If I add the toughness tests to a PQR, can I still use that PQR for another WPS without including the toughness testing? I.e, two different PQR numbers/documents but both .

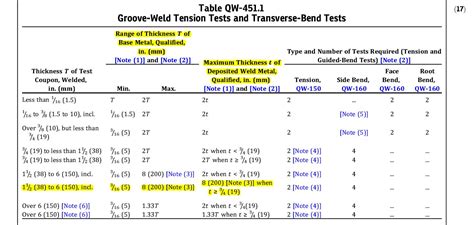

Thickness Qualification Range for PQR and WPQ. 8 Comments / ASME Section IX / By Weld Fab World. In this article we will discuss the thickness qualification range of base metal and weld metal for Procedure qualification and Welder .Based on the ASME impact test requirement, you need to make assessment to see that either your pressure vessel is exempted from impact testing, or you need to carry out the test. There are 4 steps for impact test exemption assessment. I e i need to carry one impact test on for the base metal range T/2 to T+ 6. Example : for 5 mm sample (impact test coupon) :2.5 to 10 mm qualify. for 10 mm sample 5 to 20 mm .S = Supplementary Essential Variables must be indicated on the WPS and Recorded on the PQR when Impact Testing is required. Changes to these variables when Impact testing is .

Normally you need to conduct two set of impact testing, one set in weld metal and one set in heat affected zone. This article provides you information about welding procedure qualification record (PQR) based on requirements of ASME Code .

A PQR test report is a document that contains the results of a welding procedure qualification tests. The purpose of this test is to evaluate the suitability of a welding procedure .(a) Procedure Qualification Record (PQR). The PQR is a record of variables recorded during the welding of the test coupons. It also contains the test results of the tested specimens. .

The necessary documents for a successful Welding Program are as follows: 1.Welding Procedure Specification (WPS), Procedure Qualification Record (PQR), Independent Laboratory Test Report for the PQR, Welder .

Scribd is the world's largest social reading and publishing site.

UHA-51(f)(2) requires the WPS be supported by a PQR with impact testing performed at the MDMT. We don’t meet this condition. As we have shown previously, UHA-51(a)(4)(a)(2) requires the PQR testing be performed at .This article talks about procedure qualification record (PQR) based on requirements of ASME Code Section IX. . When construction code like ASME Code Section VIII Div I requires impact testing, the impact testing must be .

Procedure Qualification Record (PQR) is a document that consists of procedures for creating and testing the sample welds, and the final results as well.PQR is a prior step before Welding Procedure Specification (WPS) document. Simply, a procedure qualification record (PQR) is a supporting document for WPS.Table 323.3.1 shows Impact test requirements for production test coupons which shows 1/2T to T+6 mm . ASME B31.3 INTERPRETATIONS Interpretation 25-29 Subject: Table 323.3.1, Welding Procedures With Impact Tests (B31.3-2012) Date Issued: April 28, 2015 File: 15-586

this heat-treated condition shall be noted on the PQR and WPS used for construction; and (-c) meet the minimum toughness requirements . 3.11.8 IMPACT TESTING OF WELDING PROCEDURES AND TEST PLATES OF FERROUS MATERIALS. 3.11.8.1 Impact Tests. (a) For steel vessels of welded construction, the impact toughness of welds and heat-affected zones .PROCEDURE QUALIFICATION RECORD (PQR) ASME Boiler and Pressure Vessel Code , Section IX Sheet 1 of 4 . (For impact test application, there are some restrictions for welding in vertical-uphill progression position; See ASME Section IX, QW-405.2) Qualified Thicknesses (Groove, Fillet): 3/16 in. (5 mm) Min., 8 in. (200 mm) Max. (Plate or Pipe)

B 31.3 impact qualification covers 5 to 16 mm, however QW 403.6 Base metal thickness qualification range 10 to 16 mm but we cant consider less than 10 mm (i e 5 to 9.9 mm only impact test qualified range and cant go more than 16 mm as per 31.3 even though QW 403.6 permit because its not qualified in impact test range) PQ Test에 필요한 내용을 사전 검토 후 이에 필요한 Test, 사양들 정리하여 Test 수행 그리고 이에 맞는 PQR, WPS 작성까지 한번에 고객사 검토, 승인 맡아드립니다. . Cutting 하여 Specimen 중 Tensile, Bend Test 용을 만들고 필요시 Impact Test 용 Specimen을 가공합니다. 여기서 . PQR 2 can be used to deposit 21mm thick weld if other essential and supplementary essential variables are same as PQR 1, since "T limits impact" (QW-403.6) has limitation only on min. thickness qualified.

wps 및 pqr 작성법 . 1. 개요 . 본 강좌는 asme code 에 의해 작성되는 wps 와 pqr 의 작성법에 대하여 설명하고자 한다.. 1-2 정의 . 1) wps . wps 란 code 의 기본요건에 따라 생산용접을 달성하기 위한 지침의 제공을 위해 준비되어, 자격 부여된 문서화된 용접 절차서이다.. 2) pqr . pqr 이란 시험편을 용접하는데 .

I have one PQR 9 mm thick, with impact test. The range qualification of qualified WPS with Impact test is 9 mm to 16 mm according QW 403.6 . My question is; What's the thick range qualification qualified by this PQR without impact test, where it's mention in ASME sect IX ? .The rules for austenitic stainless steels in this situation are summarized below. For MDMT below –320F (-196C) impact tests are REQUIRED of all raw material, weld procedure qualifications for both the weld and heat affected zone for each type of weld process, and production weld test specimens (weld and heat affected zone) for each type of weld process.

Specimens for doing mechanical testing (like bend test, impact test etc.) are carved out from the test coupon through machining. These specimens are then subjected to testing in a Laboratory. . What is a Procedure Qualification Record (PQR)? In simple terms, a PQR is a record of the events that happened during the Procedure Qualification . PQR is an abbreviation for Procedure Qualification Record. The PQR is a record of the welding variables which were used during the original qualification of the test coupon and the PQR record includes the destructive .

There are 3 types of PQR tests - Bend Test, Tensile Test & Impact Test. Let us understand these tests in detail. To know more about us, visit our website - h. PQR, or Procedure Qualification Record, is a weld test used to verify the mechanical properties of a weld. The test is carried out as per ASME Section IX or AWS D1.1. . An impact test to check for any potential fractures in the weld: If required required as per design, client or service requirements. A Macro etch examination: . I have a WPS backed up with several PQR's all of which have had CVN impacts included. In ASME sec IX QW 403.6 the minimum thickness is limited to T or 5/8" which ever is less from that normally qualified which is 3/16" or 1/16" .

This often “forgotten” requirement implies that if you weld normalized material with impact testing as a design criteria and your PQR does not indicate the heat treatment condition of the . The PQR is to ASME IX, but we need impact testing per ASME Sect. VIII, Div. 1. Thanks! Replies continue below Recommended for you. Sort by date Sort by votes . Bottom line is that PQR impact tests on a thin plate as described in the interpretation no longer support the thickness range described in the interpretation. Upvote 0 Downvote. May 10 . Procedure Qualification Record (PQR) PQR's are not required if Standard Welding Procedures are used, see below for details. This document contains details of the welding test, it must include details of all the parameters listed as variables in tables QW250 to QW265 for each process involved and all the destructive test results.

I need to produce a PQR that requires impact testing, per ASME VIII Div. 1. Is it required that the material I use for the procedure qualification be impact tested? Material used in production would be impact tested, but I am wondering if my PQR material also requires it (of course, the weld/HAZ will need tested). I'm currently looking at UG-84(d). Impact Testing of Heat Affected Zone. . (PQR-2) 8.0 mm thick test plate in 3G position by SMAW (8.0 MM). (PQR-3) 30 MM thick test plate in 1G position by SAW (30.0 MM). Tension, bend test, hardness and impact test performed on all the PQR. can you please answer to help me out. Reply. Ethan Bale. March 13, 2024 at 10:30 am Impact test on PQR aburafdi (Materials) 17 Oct 14 02:23. You can use ISO 15614-8 for welding procedure qualification of tube-to-tubesheet. The testing required: VT, PT, RT, Macro, Hardness, and push-out/pull-out (when required). Red Flag This Post. Please let us know here why this post is inappropriate. Reasons such as off-topic, duplicates . Dear Sir On your second input- We may "upgrade" existing 1G.2G.3G,4G PQRs( originally without impact testing- qualified following Table 4.5) by qualifying 3G PQR with Impact Testing. Then just have to revise the PQRs (Rev 1) and attached impact test results to each PQRs qualified earlier without CVN. Thus now i should have all the 1G,2G,3G,4G PQRs .

B31.3 PQR Impact test exemptions 1. Thread starter WE91; Start date Feb 7, 2024; Status Not open for further replies. Feb 7, 2024 #1 WE91 . Impact testing of the base metal is not required if the design minimum temperature is warmer than or equal to the temperature listed in the Min. Temp. column of Table A-1, or Table A-1M, except as .Procedure Qualification Record (PQR) Code: AWS D1.1 Sheet 1 of 4 Company Name: www.WPSAmerica.com Address: [email protected], 1 (877) WPS-WELD . We, the undersigned, certify that the statements in this record are correct and that the test welds were prepared, welded, and tested in conformance with the requirements of Section 4 of AWS D1.1 .

pqr thickness

pqr test interpretation

Resultado da 16 de set. de 2022 · VEJA VÍDEO . Homem morre após defender mulher que se recusou a dançar em bar. VEJA VÍDEO. Este é mais um vídeo enviado por leitor para o WhatsApp do "PORTAL DO ZACARIAS" (92 - (9335-3954). Curtiu? Siga o PORTAL DO ZACARIAS no Facebook, Twitter e no .

pqr impact test|pqr test interpretation